Design since both model building codes reference seismic design of steel structures to the 1997 AISC Seismic Provisions for Structural Steel Buildings Yellow Book and Supplements. The design wall thickness t shall be taken equal to 093 times the nominal wall thickness for electric-resistance-welded ERW HSS and equal to the nominal thickness for submerged-arc-welded SAW HSS ERW HSS produced to ASTM A500 and A53.

Hss End Connection Welded From Three Sides Only Structural Engineering General Discussion Eng Tips

Directly Welded HSS Connections SkyCiv Connection Design can design the following HSS to W shape connections under AISC and Eurocode Design Standards.

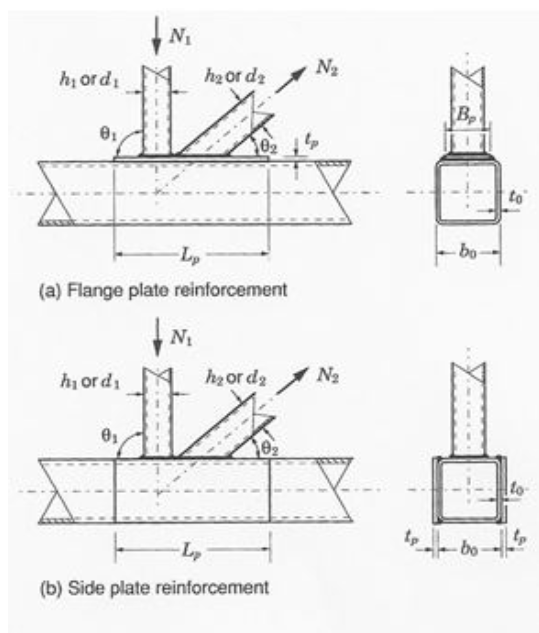

. Tp or tbu0001 1. Truss connections are connections at the panel points of a planar truss and are designed as tensioncompression connections. For a fillet weld group in an HSS connection and hence much smaller weld sizes see Table 1.

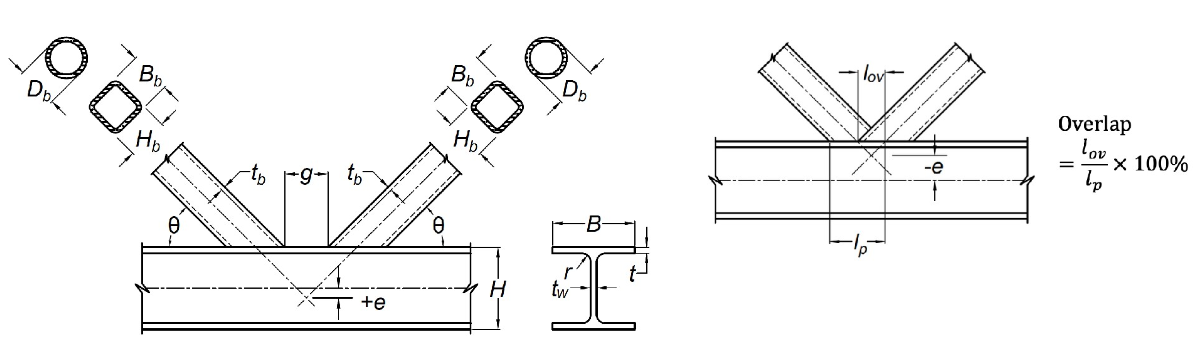

HSS Trusses and Lattice Girders Welded Connections. Welded HSS-to-HSS connections are typically used in trusses to connect branch members to main members with welds around the perimeter of the branch. The minimum effective length of a fillet weld shall be at least four times the nominal size or the effective size of the weld shall be considered not to exceed 25 of its effective length.

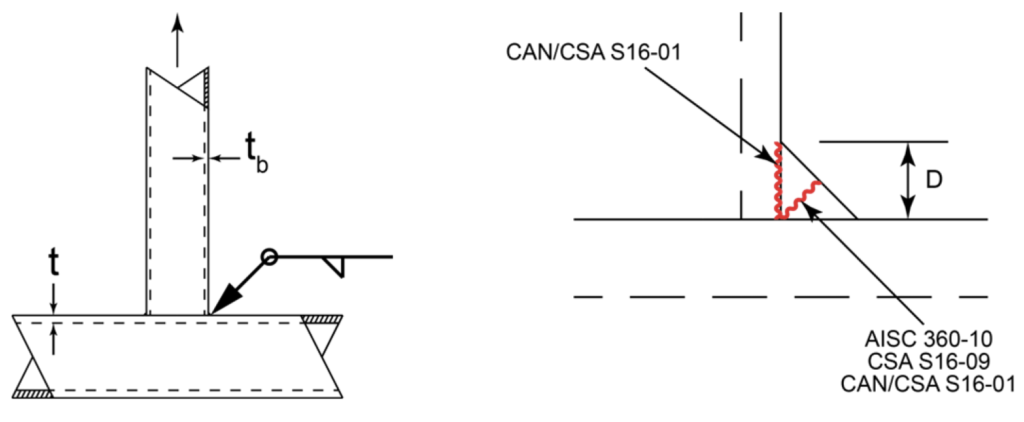

HSS welded to HSS. Designing with HSS. AISC 360 AISC 2010 has adopted Method ii in Section K Table K41 for welded connections to rectangular HSS by specifying various weld effective lengths l e for different connection types and loading situations.

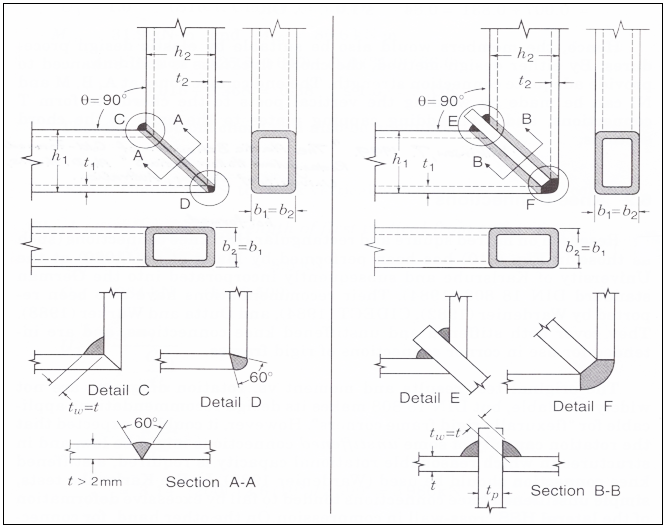

The types of connections are. 21 TYPES OF HSS WELDS The four common types of welds used in HSS connections u0002u0001 in order of preference are. Simple design models are developed.

In addition the connection has essentially no residual deformation following several cycles of inelastic story drift. The effective area shall be the ef-. Partial-joint-penetration PJP groove welds Local 3.

To attach the end plate to the HSS. So in some rate why understanding HSS connections is important is because the strength of HSS the local strength of HSS has a very integral part into the connection design. The prior edition CANCSA S16-01 included a check for shearing of the base metal at the edge of a fillet weld along the fusion face see Figure 3 which frequently governed and thus resulted in generally larger weld sizes at that time.

Single Seat Connections Single Angle all bolted or all welded or weldedbolted Double Angle all bolted or all welded or weldedbolted Single Plate all welded or weldedbolted. Directly Welded Truss Connection K Connection TY Connection. But for the sake of discussion the HSS wall strength 4616714 69 kipinch and the weld specified is 09283 27 kipinch.

The trusses usually connect at each end to a support column but they may connect to another truss forming a space frame. Generally hollow section trusses and lattice girders are welded together in the workshop and delivered to site as a unit this allows for better quality control and more efficient site erection. And what I mean by local strength is your side wall yielding your chord-wall classification the flexibility of the face of the HSS when it comes to connections.

This specification never appeared in the Manual of Steel Construction but it did appear in the HSS Connections Manual. A When the punching load Pr sinθ in a branch member is equilibrated by beam shear in the. HSS manufactured according to American Society for Test- ing and Materials ASTM standard A500 ASTM 2007a are cold-formed in tube mills and have an electric resistance welded ERW continuous seam weld.

RPMG Structural 5 Mar 20 1656. In this video I discuss the specifics of trusses with HSS including joint types fabrication costs failure modes design approaches welding and more. This weld is pro- duced without the.

This new design guide from the American Institute of Steel Construction addresses bolted and welded connections involving HSS and provides examples of the application of design provisions for various configurations of HSS connections and the applicable limit states. The transformation of steel strip into hollow structural sections HSS is the result of operations including forming welding and sizing. DESIGN OF WELDED CONNECTIONS AWS D112000 2423 Minimum Length.

HSS manufactured according to American Society for Testing and Materials ASTM standard A500 ASTM 2007a are cold-formed in tube mills and have an electric resistance welded ERW continuous. Local yielding of beam flange. Directly Welded Connection Example Check beam and HSS failure modes Transverse Plate connection AISC table K12.

HSS Design with the Latest Codes. On March 12 2013. Therefore this needs to be.

As a sequel this paper discusses the special. Flare-bevel and flare-V-groove welds dihedral Local angle dihedral 4. Hot-Dip Galvanized Architecturally Exposed Structural Steel Guide - Created in 2021 by the American Galvanizers Association this 16-page guide provides best design practices to maximize Hot-Dip Galvanizing appearance for AESS projects.

The lateral resisting systems design restrictions in both model building codes are being referenced from the ASCE-7 document on building loadings. K with two or three branches in a. HDG AESS Sample Images - Can be used to supplement project meetings to understand expectations for various categories of AESS.

Weld Design Weld design for HSS-to-HSS connections. T or Y with a single branch perpen-dicular or at an angle to the main member. Currently three methods are being used in North America for the manufacture of HSS.

HSStoHSS truss connections are defined as connections that consist of one or more branch members that are directly welded to a continuous chord that passes through the connection and shall be classified as follows. AISC Connections Section NJ and AISC Manual Part 9 HSS and Box Member Connections Section NK Selecting Standard Connections from the AISC Manual AISC Manual Parts 9 10 Seismic Connection BMA Engineering Inc. The connection initial elastic stiffness is comparable to that of a fully restrained welded connection.

There are lots of red flags here from the member sizes welds and no bending moment. ΦR n 10BtF ytb f F yp tfbf ΦR n 584 k 51 k OK 11 Directly Welded Connection Example HSS shear yieldingpunching Applicable when. Earthquake Resistant Post-Tensioned Connections to Concrete Filled HSS Columns.

Details of the two methods can be found in an earlier technical paper Welding of Hollow Structural Sections. 085B b f B-2t. Hollow structural sections HSS.

Welded Truss Connections Between Hss Branches And I Shaped Chords Steel Tube Institute

Pdh What Your Fabricator Wishes You Knew About Hss Informed Infrastructure November December 2017

Hss To Hss Connections Steel Tube Institute

Welding Of Hollow Structural Sections Steel Tube Institute

Hss Welded To Hss Structural Engineering General Discussion Eng Tips

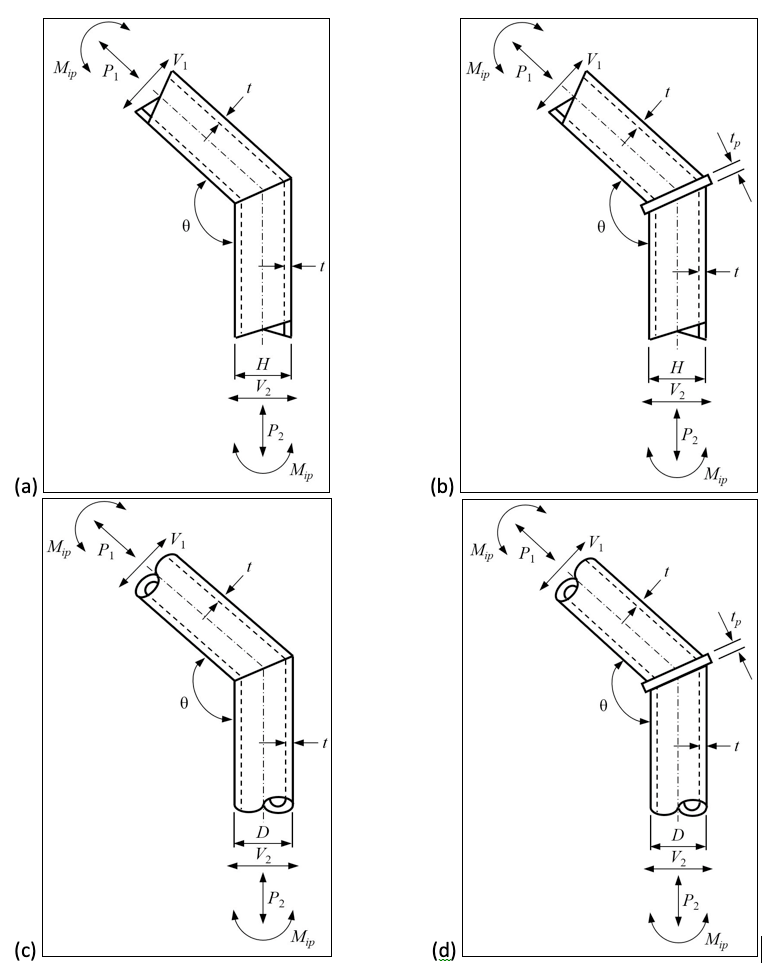

Hss Knee Connections Steel Tube Institute

Hss Knee Connections Steel Tube Institute

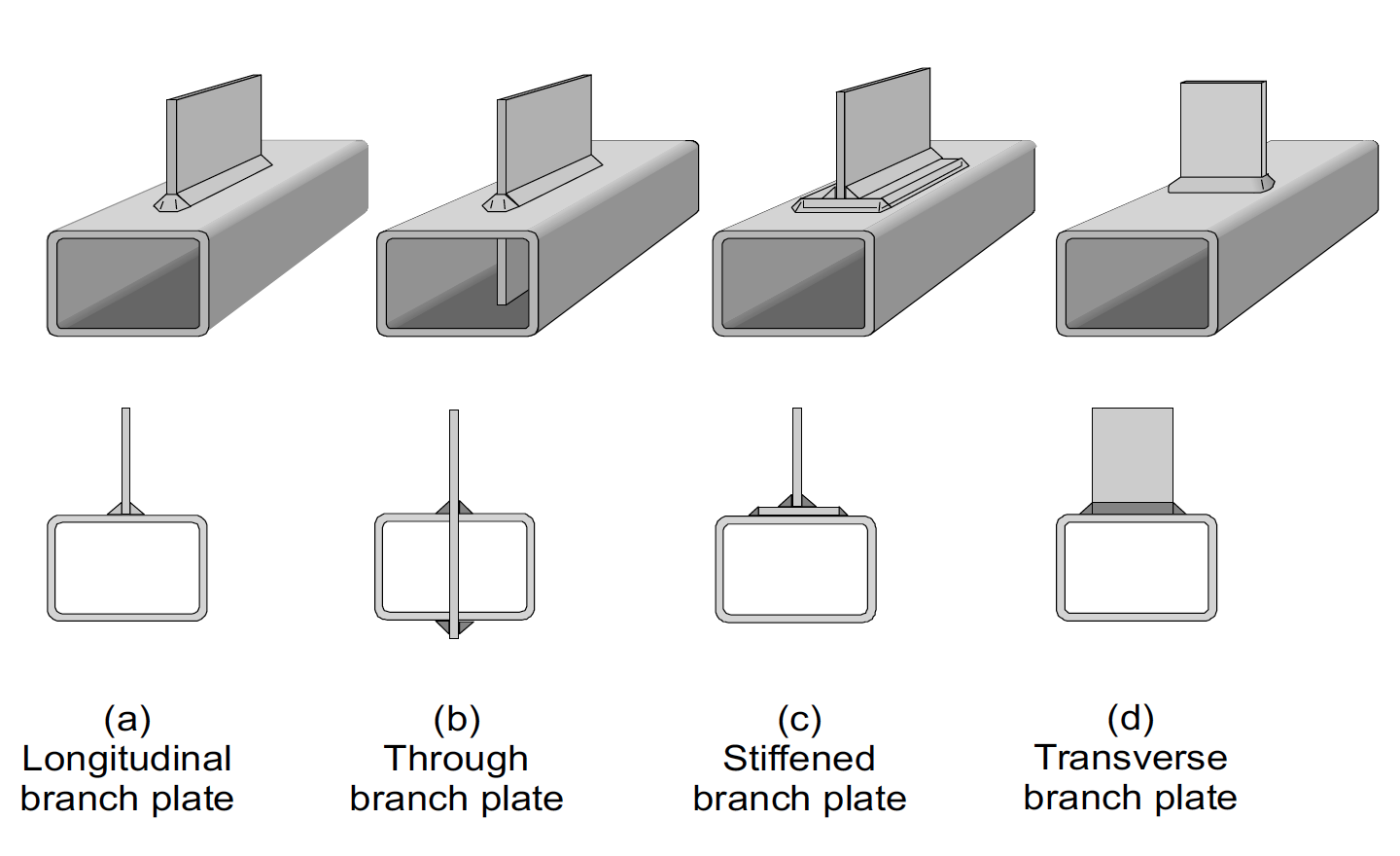

Transverse Plate To Square Rectangular Hss Connections Steel Tube Institute

0 comments

Post a Comment